In high-stakes industrial environments, even the smallest components can make a significant difference, especially when it comes to safety, regulatory compliance, and efficient operations. One such critical yet often overlooked element is the custom equipment nameplate. Far more than simple identification tags, these plates serve as essential tools for ensuring proper machine use, maintenance procedures, and safety adherence.

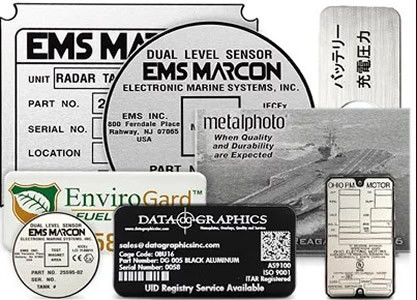

At Data Graphics Inc., we specialize in designing and manufacturing durable, high-performance nameplates tailored to meet the rigorous demands of today’s industrial applications. Whether you’re in aerospace, manufacturing, defense, or energy, our nameplates are engineered to perform reliably in the most challenging conditions.

Each product is fabricated using advanced manufacturing techniques and premium materials to ensure longevity, legibility, and industry compliance. From resisting abrasion and chemicals to withstanding extreme temperatures, our nameplates are built for endurance and clarity.

Explore how custom industrial nameplates can enhance your equipment’s reliability, streamline maintenance, and ensure safety across your facility. At Data Graphics Inc., we combine precision engineering with customer-focused service to deliver nameplate solutions that meet your exact specifications.

The Role of Custom Equipment Nameplates in Industrial Settings

Custom equipment nameplates are far more than simple labels, they are essential components of a well-functioning, safety-driven industrial operation. In fast-paced, high-risk settings, clearly marked equipment allows technicians and operators to quickly identify machine functions, capabilities, safety ratings, and maintenance requirements. These nameplates act as permanent visual guides, reducing the likelihood of human error, equipment failure, and costly operational delays.

Consider the risks of servicing complex machinery without accurate labeling. Without clear voltage ratings, torque specifications, or maintenance intervals, a technician could inadvertently cause severe damage, or worse, suffer a serious injury. Precision-engineered nameplates mitigate these risks by placing critical information exactly where it’s needed most, on the equipment itself.

At Data Graphics Inc., every nameplate we manufacture is designed for extreme durability, clarity, and compliance with regulatory standards. Whether it’s meeting OSHA labeling requirements, ANSI safety standards, or industry-specific guidelines, our nameplates help organizations stay compliant, avoid costly violations, and create a safer work environment. In fact, research consistently shows that facilities with comprehensive labeling protocols experience fewer accidents, fewer maintenance errors, and improved overall efficiency.

Beyond safety and compliance, custom nameplates also support process consistency and traceability, key factors in high-precision industries like aerospace, defense, medical manufacturing, and automotive. Accurate, long-lasting equipment labels help ensure that every process is repeatable, every part is traceable, and every product is built to spec. This not only boosts quality assurance but also supports lean manufacturing and Six Sigma initiatives.

By integrating custom industrial nameplates into your equipment and operations, you’re investing in clarity, safety, and performance, key drivers of success in today’s complex manufacturing landscape.

Types of Custom Equipment Nameplates

At Data Graphics Inc., we manufacture a diverse range of custom equipment nameplates designed to meet the specific requirements of various industries, applications, and environmental conditions. Whether you need labels for rugged outdoor equipment, medical devices, or clean-room manufacturing, we deliver nameplates that combine durability, precision, and clarity. Each nameplate is tailored to the unique conditions it will face, from extreme heat and abrasion to chemical exposure and UV radiation.

1. Metal Nameplates

Crafted from robust materials like aluminum, stainless steel, and brass, metal nameplates are built for environments where resilience and longevity are essential. They can withstand harsh weather, physical impacts, chemical exposure, and high temperatures, making them ideal for heavy industrial settings such as manufacturing plants, construction equipment, and marine applications. These plates can be screen printed, laser-engraved, or etched for lasting legibility in demanding conditions.

2. Anodized Aluminum Nameplates

Anodizing aluminum enhances its surface by increasing corrosion resistance, hardness, and color retention. These nameplates are exceptionally durable, with embedded graphics that won’t fade, peel, or wear over time. Perfect for aerospace, military, and high-spec manufacturing, anodized aluminum nameplates remain legible in high-pressure, high-vibration, or outdoor environments where other labels may degrade.

3. Laser Etched Nameplates

Laser etched nameplates feature deeply engraved text and graphics that won’t wear off, even under repeated cleaning, abrasive contact, or solvent exposure. These are particularly effective in high-touch or industrial environments, such as oil rigs, transit systems, or heavy equipment, where durability and permanence are critical. Fill options such as epoxy or baked enamel can be added for contrast and enhanced visibility.

4. Serialized and Barcode Nameplates

These nameplates incorporate serialized numbers and barcodes for asset tracking, inventory management, and workflow automation. Especially valuable in medical device manufacturing, aerospace, electronics, and logistics, they support digital traceability across the product lifecycle. Data Graphics ensures that these codes are printed or etched with precision, ensuring scannability under real-world conditions.

At Data Graphics Inc., all nameplates are custom-fabricated in-house, ensuring tight tolerances, crisp high-resolution graphics, and rugged finishes that meet or exceed industry standards. We consult with every client to determine the ideal combination of material, adhesive, finish, and marking method based on their specific application. Whether your priority is longevity, legibility, compliance, or brand presentation, we offer the right solution, engineered to perform.

Key Design Elements for Functional and Compliant Nameplates

Every custom equipment nameplate must strike the right balance between clarity, compliance, and brand identity. At Data Graphics Inc., our design process is rooted in precision and purpose, ensuring each nameplate communicates critical information effectively while standing up to the demands of its environment. We go beyond aesthetics to ensure that every element, from typography to mounting method, is optimized for readability, longevity, and regulatory compliance.

1. Font Selection

Readability starts with the right typeface. We recommend clean, sans-serif fonts such as Arial, Helvetica, or Univers, which enhance legibility from a distance and under low-light conditions. This is particularly important for safety signage, equipment instructions, and emergency information, where quick recognition can prevent accidents or costly mistakes. Our design team also considers font size, weight, and spacing to meet ANSI, OSHA, or ISO standards where applicable.

2. Color Contrast

High-contrast color combinations are essential for visibility, especially in harsh lighting, high-glare, or dim environments. For instance, black text on a yellow or white background offers excellent legibility, even from a distance or through protective equipment. We use UV-stable inks and finishes to ensure that contrast and color integrity are maintained over time, resisting fading from sunlight or chemical exposure.

3. Logo Integration

A nameplate is also an extension of your brand. We offer seamless logo integration that reinforces brand recognition without compromising functionality. Our design team ensures that logos are positioned carefully, never interfering with critical operational data, safety instructions, or regulatory markings. This approach maintains both brand presence and compliance with industry labeling guidelines.

4. Mounting Options

How a nameplate is applied affects its durability, alignment, and functionality. We offer a variety of mounting solutions, including:

- Industrial adhesives for smooth surfaces or curved applications

- Rivets or screws for permanent, vibration-resistant installation

- Magnetic backing for reusable or temporary labeling needs

Our team helps you select the most appropriate method based on the surface material, environmental exposure, and expected product lifecycle.

Why Choose Data Graphics Inc. for Custom Equipment Nameplates?

Data Graphics Inc. is a UL, ISO 9001:2015, and AS9100-certified manufacturer with over 40 years of experience in producing custom equipment nameplates for mission-critical industries, including aerospace, medical, military, and industrial manufacturing.

We offer:

- Rapid prototyping and precision manufacturing

- Material certifications and full compliance documentation

- Customized solutions with low minimum order quantities

- In-house engineering support for complex designs

With a commitment to quality, customization, and customer service, we help companies create durable, high-performance nameplates that stand the test of time.

Final Thoughts

In industrial settings where precision, safety, and reliability are non-negotiable, generic labeling simply won’t suffice. Off-the-shelf solutions often fall short when it comes to durability, regulatory compliance, and application-specific clarity. That’s why investing in custom equipment nameplates is more than a design choice, it’s a strategic business decision.

At Data Graphics Inc., we specialize in crafting high-performance nameplates that are built to withstand the rigors of industrial environments, from extreme temperatures and chemical exposure to vibration and heavy wear. Each nameplate is engineered with a purpose: to enhance operational efficiency, improve safety communication, and ensure your business meets or exceeds industry regulations.

Whether you’re in aerospace, manufacturing, energy, or electronics, our team is ready to deliver a tailored solution that aligns with your technical requirements and branding needs.

Don’t leave critical asset tracking, safety, or compliance to chance. Let Data Graphics Inc. deliver precision-engineered nameplates built for your exact needs. Call us today at 888.942.2540 or fill out our online form to request a free quote.